Our Blog

What To Know About Contract Manufacturing

Share this Article:

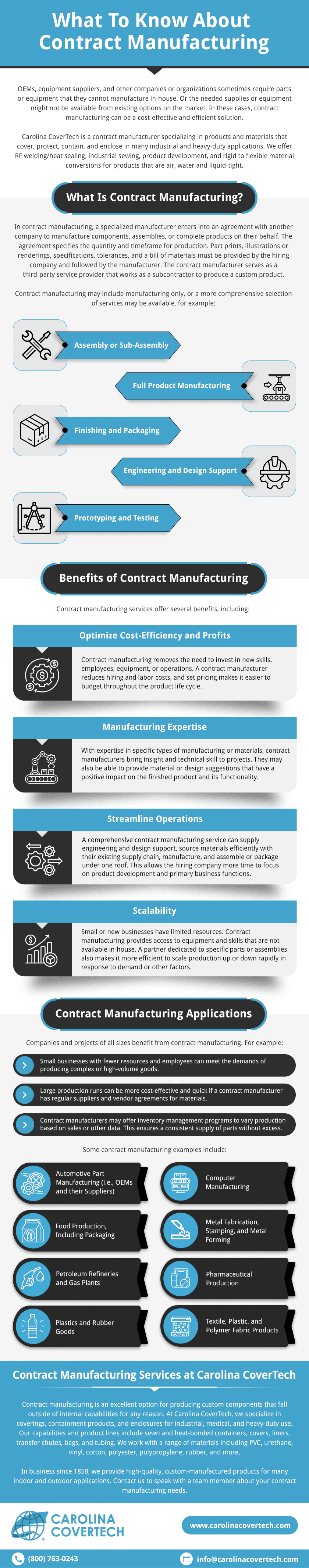

OEMs, equipment suppliers, and other companies or organizations sometimes require parts or equipment that they cannot manufacture in-house. Or the needed supplies or equipment might not be available from existing options on the market. In these cases, contract manufacturing can be a cost-effective and efficient solution.

Carolina CoverTech is a contract manufacturer specializing in products and materials that cover, protect, contain, and enclose in many industrial and heavy-duty applications. We offer RF welding/heat sealing, industrial sewing, product development, and rigid to flexible material conversions for products that are air, water and liquid-tight.

What Is Contract Manufacturing?

In contract manufacturing, a specialized manufacturer enters into an agreement with another company to manufacture components, assemblies, or complete products on their behalf. The agreement specifies the quantity and timeframe for production. Part prints, illustrations or renderings, specifications, tolerances, and a bill of materials must be provided by the hiring company and followed by the manufacturer. The contract manufacturer serves as a third-party service provider that works as a subcontractor to produce a custom product.

Contract manufacturing may include manufacturing only, or a more comprehensive selection of services may be available, for example:

- Assembly or sub-assembly

- Full product manufacturing

- Finishing and packaging

- Engineering and design support

- Prototyping and testing

Benefits of Contract Manufacturing

Contract manufacturing services offer several benefits, including:

- Optimize Cost-Efficiency and Profits: Contract manufacturing removes the need to invest in new skills, employees, equipment, or operations. A contract manufacturer reduces hiring and labor costs, and set pricing makes it easier to budget throughout the product life cycle.

- Manufacturing Expertise: With expertise in specific types of manufacturing or materials, contract manufacturers bring insight and technical skill to projects. They may also be able to provide material or design suggestions that have a positive impact on the finished product and its functionality.

- Streamline Operations: A comprehensive contract manufacturing service can supply engineering and design support, source materials efficiently with their existing supply chain, manufacture, and assemble or package under one roof. This allows the hiring company more time to focus on product development and primary business functions.

- Scalability: Small or new businesses have limited resources. Contract manufacturing provides access to equipment and skills that are not available in-house. A partner dedicated to specific parts or assemblies also makes it more efficient to scale production up or down rapidly in response to demand or other factors.

Contract Manufacturing Applications

Companies and projects of all sizes benefit from contract manufacturing. For example:

- Small businesses with fewer resources and employees can meet the demands of producing complex or high-volume goods.

- Large production runs can be more cost-effective and quick if a contract manufacturer has regular suppliers and vendor agreements for materials.

- Contract manufacturers may offer inventory management programs to vary production based on sales or other data. This ensures a consistent supply of parts without excess.

Some contract manufacturing examples include:

- Automotive part manufacturing (i.e., OEMs and their suppliers)

- Computer manufacturing

- Food production, including packaging

- Metal fabrication, stamping, and metal forming

- Petroleum refineries and gas plants

- Pharmaceutical production

- Plastics and rubber goods

- Textile, plastic, and polymer fabric products

CONTRACT MANUFACTURING SERVICES AT CAROLINA COVERTECH

Contract manufacturing is an excellent option for producing custom components that fall outside of internal capabilities for any reason. At Carolina CoverTech, we specialize in coverings, containment products, and enclosures for industrial, medical, and heavy-duty use. Our capabilities and product lines include sewn and heat-bonded containers, covers, liners, transfer chutes, bags, and tubing. We work with a range of materials including PVC, urethane, vinyl, cotton, polyester, polypropylene, rubber, and more.

In business since 1858, we provide high-quality, custom-manufactured products for many indoor and outdoor applications. Contact us to speak with a team member about your contract manufacturing needs.