CUSTOM Environmental covers

Product & Material Information

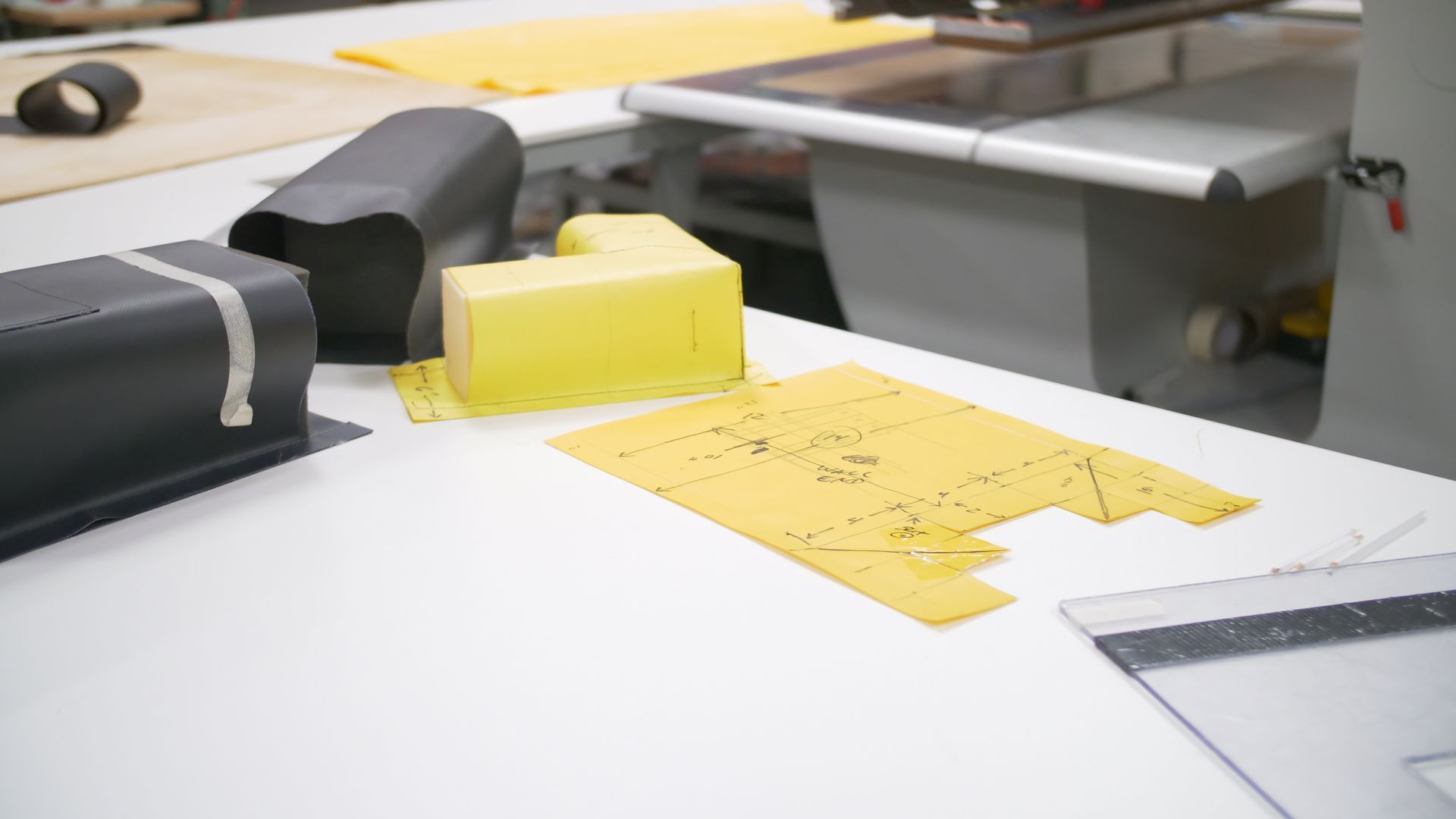

We manufacture industrial containers to meet your needs. These containers are often used to hold, transport, or store industrial related products and materials. Size and shape is based on what type of item you want to contain and quantity or size. We will work with you to select the best material and accessories for your container.

Products

- Containers

- Covers

- Culvert extensions

- Storm water control products

- Tubing

- Water booms

Materials

Vinyl Coated Polyester:

Tough mesh fabric coated with molten vinyl (PVC) used for truck covers, lumber tarps, asphalt tarps, containment booms, insulated bulkheads, dock seals, concrete curing blankets, and laundry carts.

Vinyl Laminated Polyester:

Mesh fabric laminated with 2 layers of vinyl (PVC) film used for gym mats, wall pads, protective pads, gym diverters, curtains, netting headers, laundry carts, and general purpose covers.

Urethane-Coated Polyester or Nylon:

Heavy mesh fabric coated with molten Urethane used for heavy usage and for applications that involve strong chemicals and fuels.

Plastic Films:

Polyethylene films and reinforced material used for liquid bladders, secondary containment, products, and short term covers.

PVC Films

Polypropylene

Chemical Resistant Geomembrane:

DuPont Dacron Polyester that has been molecularly coated with sophisticated compounds that are minimally degradable in harsh environments used for application that involve strong chemicals and fuels.

Accessories

- Bungee

- Elastic

- Grommets

- Snaps

- Tie downs

- Velcro

- Zippers

Applications

- Chemical containment

- Hydrocarbon containment

- Water containment

- Water diversion

MAnufacturing Information

Secondary Operations

- Digital printing

- Embroidery

- Screen printing

Equipment

- Bar Tacker

- Binder

- Clicker Die

- Double needle machine

- Grommet Machine

- Hot Wedge Heat Sealer

- Radio Frequency Welder

- Single needle

- Thermal Impulse Heat Sealer

General Information

Industries Served

- Construction

- DOT

- Hazmat

- Municipalities

- Plants and Industry

Quantities

Based on customer requirement or need.

Lead Time

Generally 2 to 4 weeks depending upon the product complexity and quantity desired.

Quality

Our products will meet product and customer requirements and specifications. We are committed to lean manufacturing principles and continuous improvement. We are certified under numerous customer quality assurance programs.

Contact Us Today!

We are ready to answer your questions and get going on your product. Let us know how we can help!

Partner with carolina covertech today!

At Carolina CoverTech, we specialize in crafting technical fabric product solutions across a variety of industries. With a portfolio of thousands of projects completed, our team is dedicated to delivering solutions that are customized to your specific needs.

For more information about our products and services or to discuss your next project, please contact us today. We are eager to work with you to create a tailored solution that perfectly fits your requirements.

resources

Explore expert insights, industry trends, and actionable advice tailored to help you stay ahead in the competitive landscape. Whether you're an entrepreneur or business owner, we're here to empower your growth and success.

TELL US ABOUT YOUR PROJECT

Tell us as much or as little as you would like. We have built our business by keeping our word and honoring intellectual property. If you’d rather discuss your concepts over the phone, please give us a call at (800) 763-0243.